Future Horizons: Model Context Protocol (MCP) and Autonomous Systems in Manufacturing PLM

Executive Summary

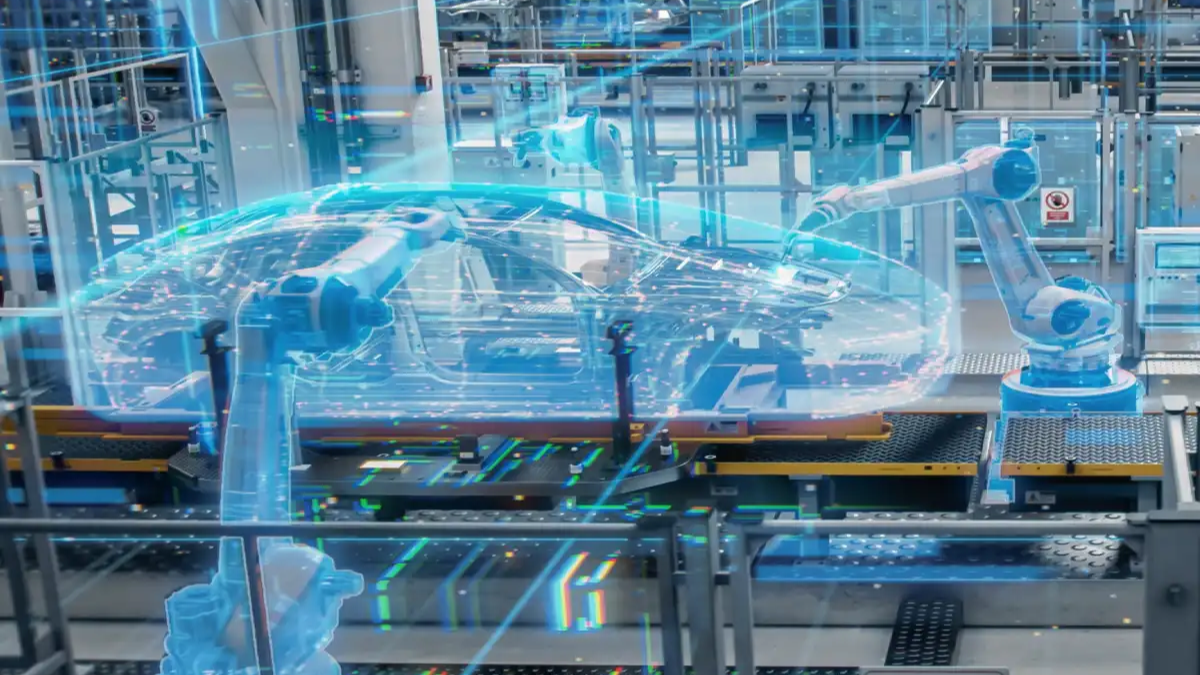

This article explores the transformative potential of Model Context Protocol (MCPs) and autonomous agent systems within manufacturing and Product Lifecycle Management (PLM) environments. Building on our previous analysis of current PLM implementation challenges, we project a technological trajectory for the next 3-5 years, identifying key inflection points, technical prerequisites, and strategic implementation pathways. The analysis focuses on practical applications that extend beyond theoretical frameworks to address specific manufacturing and PLM use cases.

Introduction: Beyond Current Agent Architectures

Current implementations of AI in PLM environments predominantly focus on narrow, task-specific applications with limited cross-system capabilities. The transition toward Model Context Protocol (MCP) represents a fundamental architectural shift that warrants systematic analysis. This article examines how the confluence of several technological advancements—semantic data layers, event-driven architectures, and foundational AI models—creates the conditions for truly autonomous manufacturing systems.

Section 1: Technical Foundations for Model Context Protocol in PLM

1.1 Architectural Prerequisites

The implementation of effective MCPs in manufacturing contexts requires several foundational elements:

- Knowledge Graph Integration: Transition from traditional relational data models to knowledge graphs that maintain semantic relationships across domains

- Event Mesh Infrastructure: Implementation of event-driven architectures that enable real-time responsiveness across traditionally siloed systems

- Computational Resource Requirements: Analysis of edge, fog, and cloud computing distributions required to support agent operations at different levels of the manufacturing stack

1.2 Agent Specialization Taxonomy

We propose a systematic classification of manufacturing-specific agent types with distinct capabilities:

- Environmental Perception Agents: Continuous monitoring and interpretation of manufacturing environment data

- Process Optimization Agents: Dynamic adjustment of manufacturing parameters based on quality, efficiency, and cost metrics

- Supply Chain Integration Agents: Coordination of material flows across organizational boundaries

- Engineering Design Assistants: Augmentation of human design processes through generative and analytical capabilities

- Compliance and Quality Monitoring Agents: Automated verification of regulatory and quality requirements

1.3 Quantitative Performance Metrics

Establishing concrete evaluation frameworks for agent performance in manufacturing contexts:

- Decision Quality Metrics: Precision, recall, and F1 scores for agent decision processes

- System Responsiveness Parameters: Latency measurements across distributed agent networks

- Manufacturing-Specific ROI Models: Calculation methodologies for cost-benefit analysis of agent implementations

Section 2: Use Case Analysis: From Current State to Future Implementation

2.1 Engineering Change Management Evolution

Current State:

- Manual impact analysis with significant oversight

- Spreadsheet-based change tracking

- Sequential approval workflows

Transitional Implementation:

- AI-assisted impact prediction with human verification

- Semi-structured change data with AI interpretation

- Parallel processing with AI-guided prioritization

Full MCP Implementation:

- Autonomous impact assessment and change propagation across systems

- Knowledge graph-based change representation with causal relationships

- Dynamic, risk-adjusted approval routing optimized in real-time

2.2 Autonomous Quality Management Systems

Current State:

- Statistical process control with human intervention

- Manual root cause analysis

- Periodic quality reviews

Transitional Implementation:

- Predictive quality models with recommended actions

- AI-assisted causal analysis with human verification

- Continuous monitoring with exception alerts

Full MCP Implementation:

- Autonomous quality control with closed-loop corrective actions

- Automated multi-factor root cause determination and systemic correction

- Proactive system adaptation to prevent quality deviations

2.3 Digital Twin Orchestration

Current State:

- Static digital representations

- Manual synchronization between physical and digital assets

- Isolated digital twins with limited cross-system interaction

Transitional Implementation:

- Limited dynamic simulations with human-guided scenarios

- Semi-automated data reconciliation

- Federated digital twins with manual integration points

Full MCP Implementation:

- Autonomous scenario generation and system optimization

- Continuous bidirectional synchronization with autonomous validation

- Interoperable digital twin ecosystem with agent-mediated interactions

Section 3: Technological Implementation Roadmap

3.1 Infrastructure Preparation Phase (0-18 months)

- Knowledge graph implementation for core product data

- Event mesh deployment for cross-system communication

- Edge computing infrastructure for agent hosting

- Data quality baseline establishment and enhancement

3.2 Limited Agent Deployment Phase (18-36 months)

- Implementation of specialized agents for well-defined use cases

- Human-in-the-loop oversight mechanisms

- Performance monitoring and benchmarking

- Organizational capability development

3.3 Autonomous Agent Ecosystem Development (36-60 months)

- Inter-agent communication protocols

- Dynamic agent orchestration systems

- Reduced human oversight with exception handling

- Cross-organizational agent interactions

Section 4: Competitive Vendor Landscape Analysis

4.1 PLM Vendor Positioning

Aras:

- Current Agent Capabilities: Limited agent-based workflows, strong API foundation including configurable web services (CWS)

- Architectural Readiness: Microservices architecture supports distributed agents

- Strategic Trajectory: Strategic focus on low-code configuration and integration

Siemens:

- Current Agent Capabilities: Advanced simulation capabilities, domain-specific agents

- Architectural Readiness: Comprehensive digital twin framework

- Strategic Trajectory: Vertical integration of design, manufacturing, and service agents

PTC:

- Current Agent Capabilities: IoT-focused agents, AR/VR integration

- Architectural Readiness: ThingWorx platform provides agent hosting environment

- Strategic Trajectory: Expansion into service-based applications (ServiceMax) and remote monitoring

Dassault Systèmes:

- Current Agent Capabilities: 3D-centric agents, virtual twin emphasis

- Architectural Readiness: 3DEXPERIENCE platform iPaaS as integration layer with Netvibes backplane and NuoDB graph database

- Strategic Trajectory: Comprehensive coverage across design, simulation, and manufacturing

4.2 Manufacturing Technology Provider Positioning

GE Digital:

- Current Agent Capabilities: Asset performance management agents

- Architectural Readiness: Predix platform as agent hosting environment

- Strategic Trajectory: Focus on predictive maintenance and operational efficiency

ABB:

- Current Agent Capabilities: Process automation agents, robot control systems

- Architectural Readiness: ABB Ability platform for agent deployment

- Strategic Trajectory: Integration of OT and IT systems through agent mediation

Rockwell Automation:

- Current Agent Capabilities: Manufacturing execution agents

- Architectural Readiness: FactoryTalk platform for agent coordination

- Strategic Trajectory: Emphasis on factory floor integration and operational visibility

Honeywell:

- Current Agent Capabilities: Process control agents, safety monitoring

- Architectural Readiness: Forge platform for industrial applications

- Strategic Trajectory: Focus on process industries and regulatory compliance

4.3 Emerging Specialized Solution Providers

Several specialized vendors are developing purpose-built agent solutions for manufacturing contexts:

- Cognitive Process Automation: Startups focusing on autonomous workflow execution

- Manufacturing Intelligence Platforms: Specialized analytics and recommendation engines

- Supply Chain Orchestration Systems: Agent-based logistics and inventory optimization

- Quality Prediction Systems: Specialized defect prevention agents

Section 5: Strategic Implementation Considerations

5.1 Risk Management Framework

Implementation of autonomous agent systems introduces several categories of risk requiring systematic management:

- Technical Risks: System failure modes, security vulnerabilities, performance degradation

- Operational Risks: Process disruption, transition management, productivity impacts

- Organizational Risks: Skill gaps, change resistance, governance challenges

- Strategic Risks: Vendor lock-in, technology obsolescence, competitive positioning

5.2 ROI Calculation Methodology

Proposed framework for calculating the return on investment for autonomous agent implementations:

- Cost Components: Implementation costs, ongoing maintenance, training, infrastructure

- Benefit Categories: Productivity improvements, quality enhancements, time-to-market reduction

- Risk Adjustment Factors: Implementation risk, adoption rate, technology maturity

5.3 Legal and Ethical Considerations

The deployment of autonomous manufacturing agents raises several legal and ethical considerations:

- Liability Allocation: Responsibility assignment for agent-induced errors

- Intellectual Property Implications: Ownership of agent-generated designs and processes

- Workforce Impact Management: Skills transition and job redefinition strategies

- Data Governance Requirements: Cross-organizational data sharing and usage policies

Conclusion: Strategic Positioning for the Autonomous Manufacturing Era

The transition to Model Context Protocol represents a fundamental shift in how manufacturing organizations will manage product lifecycles. Organizations that systematically develop both the technical infrastructure and organizational capabilities to leverage autonomous agents will achieve significant competitive advantages through:

- Accelerated Innovation Cycles: Reduction in design-to-production timeframes

- Enhanced Product Quality: Proactive quality management through continuous monitoring

- Operational Efficiency: Optimization of manufacturing processes through real-time adjustment

- Supply Chain Resilience: Improved adaptability to disruptions through autonomous coordination

- Knowledge Retention: Preservation of organizational expertise in agent-based systems

The most successful implementations will balance technological advancement with pragmatic implementation strategies, recognizing that the evolution toward fully autonomous manufacturing systems requires a measured, systematic approach that builds organizational capabilities alongside technological infrastructure.

What is your strategy for integrating AI and MCP into your engineering and manufacturing processes? Please Like, Comment, and Share.