Chapter 6 - From Parametric Roots to Direct Evolution: The Rise of Hybrid Modeling in CAD Kernels

While Autodesk’s decision to fork ACIS and build ShapeManager underscored the strategic value of kernel independence, it also highlighted another emerging challenge: evolving those kernels to keep pace with user expectations. As we have seen, in the early 2000s, CAD users were increasingly demanding flexibility—not just in terms of vendor lock-in, but in how they could model. The rigid, feature-driven workflows of traditional parametric CAD were giving way to a desire for more intuitive, geometry-centric interaction.

The evolution of geometric modeling in CAD has long been framed as a rivalry between two approaches: parametric modeling and direct modeling. For decades, CAD systems were architected around one or the other, each championing different priorities. But over time, these distinctions began to blur as major modeling kernels integrated support for both paradigms. Today, hybrid modeling is the norm rather than the exception.

Parametric Modeling: Constraint-Driven Precision

Parametric modeling, popularized in the 1980s and 1990s by systems like Pro/ENGINEER and CATIA V5, is built around the idea of design intent. In this approach, geometry is defined not just by shapes but by a hierarchy of features, constraints, and dimensional parameters. These parameters drive geometry updates—change a number, and the model updates predictably.

Strengths:

- Highly structured

- Reproducible and editable

- Ideal for controlled design processes (e.g. regulatory compliance, manufacturing constraints)

Limitations:

- Can be rigid and slow to edit

- Complex history trees become fragile

- Not ideal for conceptual or iterative modeling

Direct Modeling: Geometry Without Baggage

Direct modeling, by contrast, emerged in tools like CoCreate and later SpaceClaim. It allows engineers to push, pull, and reshape geometry directly without being limited by parametric constraints or feature trees. The goal is speed and flexibility—particularly useful for conceptual design, simulation prep, or editing models from external sources.

Strengths:

- Fast and intuitive

- Great for legacy data and concept work

- Excellent for multi-CAD workflows

Limitations:

- Lacks design intent unless re-parameterized

- Less predictable for controlled design revisions

The Hybrid Breakthrough: Integrating Both Worlds

As users increasingly demanded the best of both worlds, CAD vendors and kernel developers began to integrate direct editing capabilities into parametric systems, and vice versa. This was not merely a UI change—it required deep changes at the kernel level to handle both representations and allow interoperability.

Milestone 1: CATIA V5 and CGM (1999)

Dassault Systèmes' CATIA V5, released in 1999 with the CGM kernel, was among the first major platforms to enable hybrid modeling. Though its UI still leaned parametric, the underlying kernel allowed for operations that bypassed strict history-based editing. CGM supported feature-based parametric modeling while also enabling operations like Boolean edits or surface reshaping without complete regeneration.

Milestone 2: Siemens' Synchronous Technology (2008)

The breakthrough for Parasolid came in 2008 when Siemens introduced Synchronous Technology with Solid Edge ST1, followed shortly by NX 7. This innovation combined the constraint solving and feature recognition of parametric systems with the direct geometry manipulation of direct modelers, tightly integrated at the Parasolid kernel level. It allowed users to apply direct edits while preserving (or re-deriving) design intent.

Milestone 3: PTC Wildfire 5.0 and Creo Flexible Modeling (2009–2011)

PTC took a different path. Starting with Wildfire 5.0 in 2009, it introduced the Flexible Modeling Extension (FMX), a set of tools for direct editing of parametric geometry. When PTC launched Creo in 2011, FMX was fully integrated into Creo Parametric, allowing users to push and pull geometry while retaining key constraints and relationships—implemented directly in the Granite kernel.

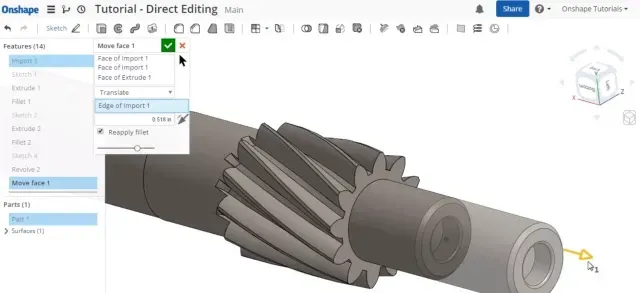

Milestone 4: Onshape and Cloud-Native Hybrid Modeling (2019)

In 2019, Onshape—a fully cloud-native CAD platform built on the Parasolid kernel—introduced its own flavor of hybrid modeling. While Onshape had supported parametric design from its inception, it added direct editing capabilities deeply integrated with its collaborative, version-controlled environment. Leveraging the flexibility of Parasolid and the scalability of the cloud, Onshape delivered hybrid modeling as a seamless, real-time experience for distributed teams.

Also in 2019, Siemens announced Convergent Modeling in their Parasolid kernel permitting both feature- and facet-based modeling at the core foundation of their modeler giving users unprecedented power over creating complex surfaces while maintaining geometric integrity.

Notable Absence: ACIS and Fragmented Support

Unlike Parasolid, CGM, or Granite, the ACIS kernel has seen more fragmented adoption of hybrid modeling. While it powers tools like BricsCAD and was once used in Inventor, few ACIS-based systems offer native support for deeply integrated parametric+direct workflows at the kernel level. Instead, hybridization—when it exists—is often handled at the application layer.

Other Players and Proprietary Paths

While the major CAD vendors rely on well-known kernels like Parasolid, CGM, and Granite, a few niche tools follow different strategies. ZW3D and VariCAD use proprietary kernels, allowing them to tightly control modeling behavior at the cost of ecosystem integration. IronCAD, uniquely, uses a dual-kernel architecture, incorporating both ACIS and Parasolid. This provides users with access to both direct and parametric tools within a single environment—albeit with some added complexity.

Conclusion: The Hybrid Kernel Era

Today, nearly every major CAD system offers hybrid modeling, but how deeply this is supported depends on kernel capabilities. The shift from "parametric vs. direct" to "parametric + direct" has redefined modeling expectations and transformed how engineers interact with 3D geometry. Far from being a mere UI convenience, hybrid modeling reflects a fundamental shift in kernel architecture, data structures, and user philosophy.

Before we talk about some of the more technological aspects of the MCAD world, let's take a detour through the mathematical underpinnings of this world!