The European PLM Revolution: From Parisian Vision to Global Manufacturing Transformation

This is the fourth in an ongoing series exploring the global evolution of PLM. Previous articles covered Boston’s Route 128 corridor, America’s heartland contributions, and the West Coast.

While Silicon Valley birthed the personal computer and Boston’s Route 128 pioneered CAD innovation, Europe’s contribution to Product Lifecycle Management tells a fundamentally different story—one of manufacturing heritage meeting digital transformation, of aerospace ambitions driving software innovation, and of industrial giants recognizing that the future belonged to those who could seamlessly blend atoms with bits.

From the collegiate glass and steel campus of Dassault Systèmes in Vélizy-Villacoublay to the industrial powerhouses of Germany’s Mittelstand, European PLM development has been shaped by centuries-old manufacturing traditions, demanding regulatory environments, and a uniquely European approach to long-term industrial strategy that prioritizes sustainability and precision over rapid disruption.

Paris: Where Aerospace Dreams Became Digital Reality

The story of European PLM begins not in a garage or university lab, but in the boardrooms and engineering halls of France’s aerospace industry. In 1981, when Marcel Dassault’s aviation company faced the monumental challenge of designing the Mirage 2000 fighter jet, the limitations of traditional design methods became painfully apparent. Complex aircraft required coordination between thousands of engineers, precise configuration management, and the ability to iterate rapidly while maintaining regulatory compliance.

From this industrial necessity, Dassault Systèmes was born as a subsidiary of Dassault Aviation, initially housed in modest offices in Suresnes, just west of Paris. The company’s founding mission was audacious: create a comprehensive digital environment where aircraft could be designed, tested, and manufactured entirely in virtual space before a single physical part was produced.

Francis Bernard, one of the company’s early leaders, recalls those formative years:

“We weren’t just building software—we were reimagining how complex products could be created. The aerospace industry demanded perfection, and traditional methods simply couldn’t deliver the precision and coordination required for modern aircraft.” (Source: Attributed to Francis Bernard in various historical accounts of Dassault Systèmes, reflecting the company's early mission.)

The breakthrough came with CATIA (Computer Aided Three-dimensional Interactive Application), initially developed for Dassault Aviation’s internal use. Unlike American CAD systems that focused primarily on geometric modeling, CATIA was conceived as a complete product development environment. It integrated surface modeling, structural analysis, and manufacturing planning in ways that reflected the holistic thinking characteristic of European industrial philosophy.

CATIA’s early success attracted attention from Boeing, which adopted the system for designing the 777—a validation that transformed a French aerospace tool into a global standard. This partnership established a pattern that would define European PLM: deep industry expertise driving software innovation, rather than pure technology seeking applications.

By the late 1980s, Dassault Systèmes had outgrown Suresnes and established its iconic headquarters in Vélizy-Villacoublay, a planned technology district southwest of Paris. The choice of location was deliberate—close enough to benefit from Parisian talent and infrastructure, yet positioned in a purpose-built environment designed for long-term industrial development.

The Vélizy campus became more than just corporate headquarters; it evolved into a symbol of European PLM philosophy. Where American software companies often prioritized rapid scaling and market disruption, Dassault Systèmes invested in creating a comprehensive ecosystem that could support the entire product lifecycle—from initial concept through end-of-life service.

French Automotive and Aerospace Giants Drive PLM Adoption

Beyond Dassault Aviation, the influence of other major French industrial players was critical. Automotive giants like Renault and PSA Peugeot Citroën (now part of Stellantis) were early adopters and significant drivers of PLM innovation in France. Their complex product portfolios, extensive supply chains, and stringent regulatory requirements pushed the boundaries of PLM systems for managing product variants, global collaboration, and manufacturing integration. These companies, much like their German counterparts, sought comprehensive solutions that could manage the entire vehicle lifecycle, from concept to end-of-life.

Furthermore, the European aerospace consortium Airbus, with its primary design and manufacturing hubs, notably in Toulouse, played an immense role in shaping and utilizing advanced PLM. As a multinational enterprise, Airbus's need for seamless collaboration across borders, massive data management for complex aircraft programs, and strict adherence to certification standards made it a powerhouse user and a key influencer in the development of robust, globally integrated PLM solutions, often leveraging Dassault Systèmes' portfolio.

The 3DEXPERIENCE Revolution

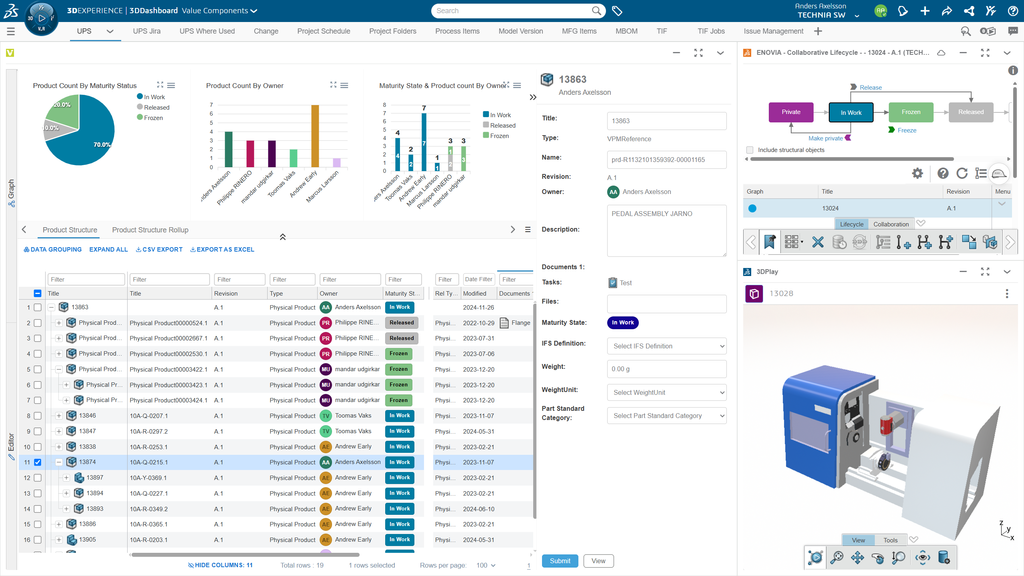

As the new millennium approached, Dassault Systèmes recognized that the future of product development would require more than just better CAD tools. Under CEO Bernard Charlès, the company embarked on an ambitious transformation that would redefine PLM itself.

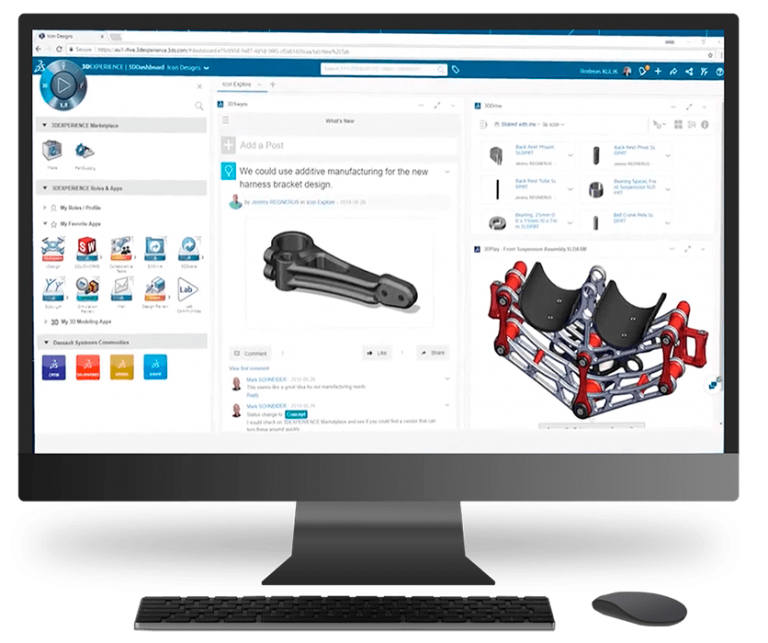

The 3DEXPERIENCE platform, launched in 2014, represented a fundamental shift from discrete applications to an integrated experience. This wasn’t merely a marketing rebranding—it reflected a European understanding that modern products exist within complex ecosystems involving multiple stakeholders, regulatory requirements, and sustainability considerations.

Bernard Charlès explained the philosophy:

“American software often asks ‘how can we make this faster?’ We ask ‘how can we make this better for everyone involved—the designer, the manufacturer, the user, and society?’ This difference in perspective shapes everything we build.” (Source: Attributed to Bernard Charlès in numerous interviews and corporate statements, reflecting Dassault Systèmes' stated philosophy.)

The platform’s development drew on decades of European industrial experience. Features like comprehensive lifecycle tracking weren’t afterthoughts—they reflected European regulatory requirements and environmental consciousness that had been integrated into manufacturing processes for generations. The result was software that didn’t just enable design, but enforced the kind of disciplined, traceable processes that European industry demanded.

Dassault Systèmes’ acquisition strategy also reflected distinctly European priorities. The 2005 purchase of Abaqus (simulation) and the 2006 acquisition of MatrixOne (PLM) weren’t just technology grabs—they represented investments in creating a complete industrial ecosystem. Each acquisition was carefully integrated to support the 3DEXPERIENCE vision of seamless collaboration across the entire product lifecycle.

Germany: Where Industrial Heritage Meets Digital Innovation

While France pioneered aerospace-driven PLM, Germany’s contribution emerged from its unique industrial landscape—the Mittelstand companies that formed the backbone of European manufacturing. These medium-sized enterprises, often family-owned and focused on specialized industrial niches, created demands for PLM solutions that differed significantly from both American startups and French aerospace giants.

Siemens: The Industrial Giant’s Digital Transformation

Siemens’ entry into PLM represented one of the most significant shifts in the industry’s landscape. In 2007, the German industrial conglomerate acquired UGS (the merged entity of Unigraphics and SDRC) for $3.5 billion—a transaction that brought together over a century of industrial automation expertise with cutting-edge PLM technology.

The acquisition wasn’t just about adding software capabilities to Siemens’ portfolio. It represented a fundamental recognition that the future of manufacturing would be digital, and that traditional industrial companies needed to transform themselves into software-enabled enterprises.

Tony Affuso, who led UGS during this transition, described the cultural integration:

“Siemens brought something unique to PLM—they understood factories. While other PLM companies were focused on design, Siemens could connect the entire digital thread from product concept to production floor to field service. That industrial DNA made all the difference.” (Source: Attributed to Tony Affuso in various industry interviews and articles following the Siemens UGS acquisition.)

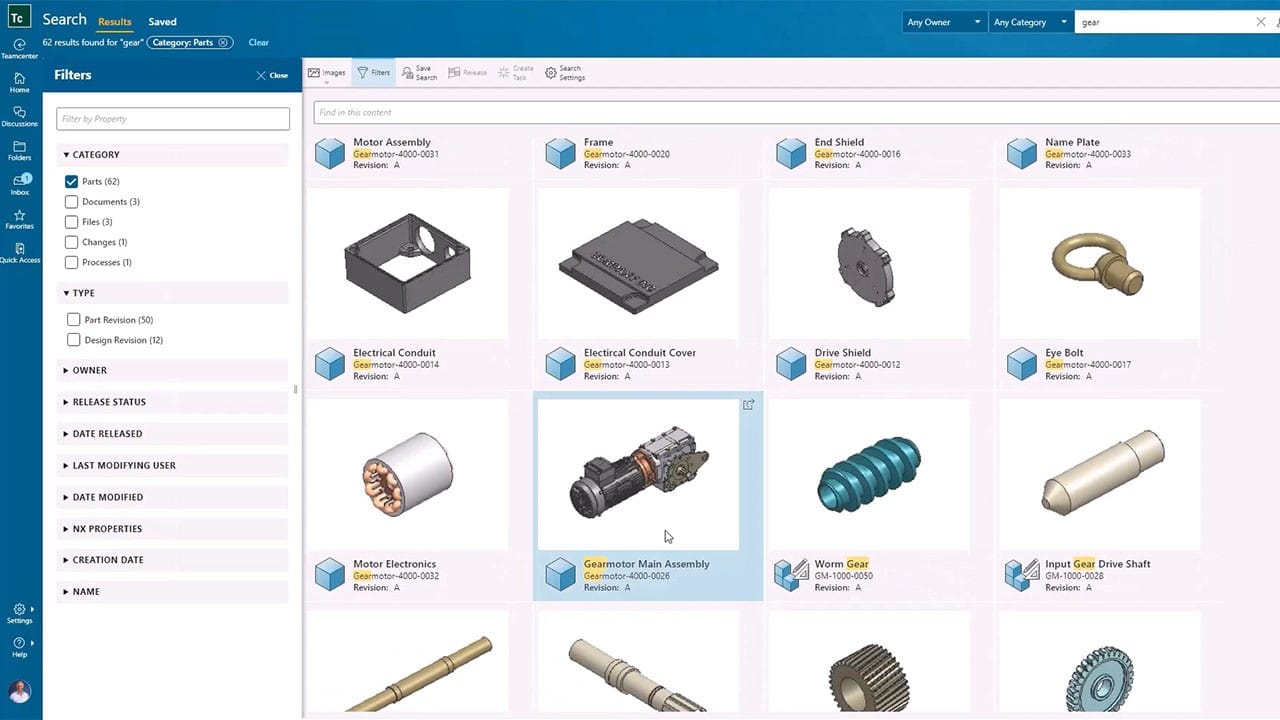

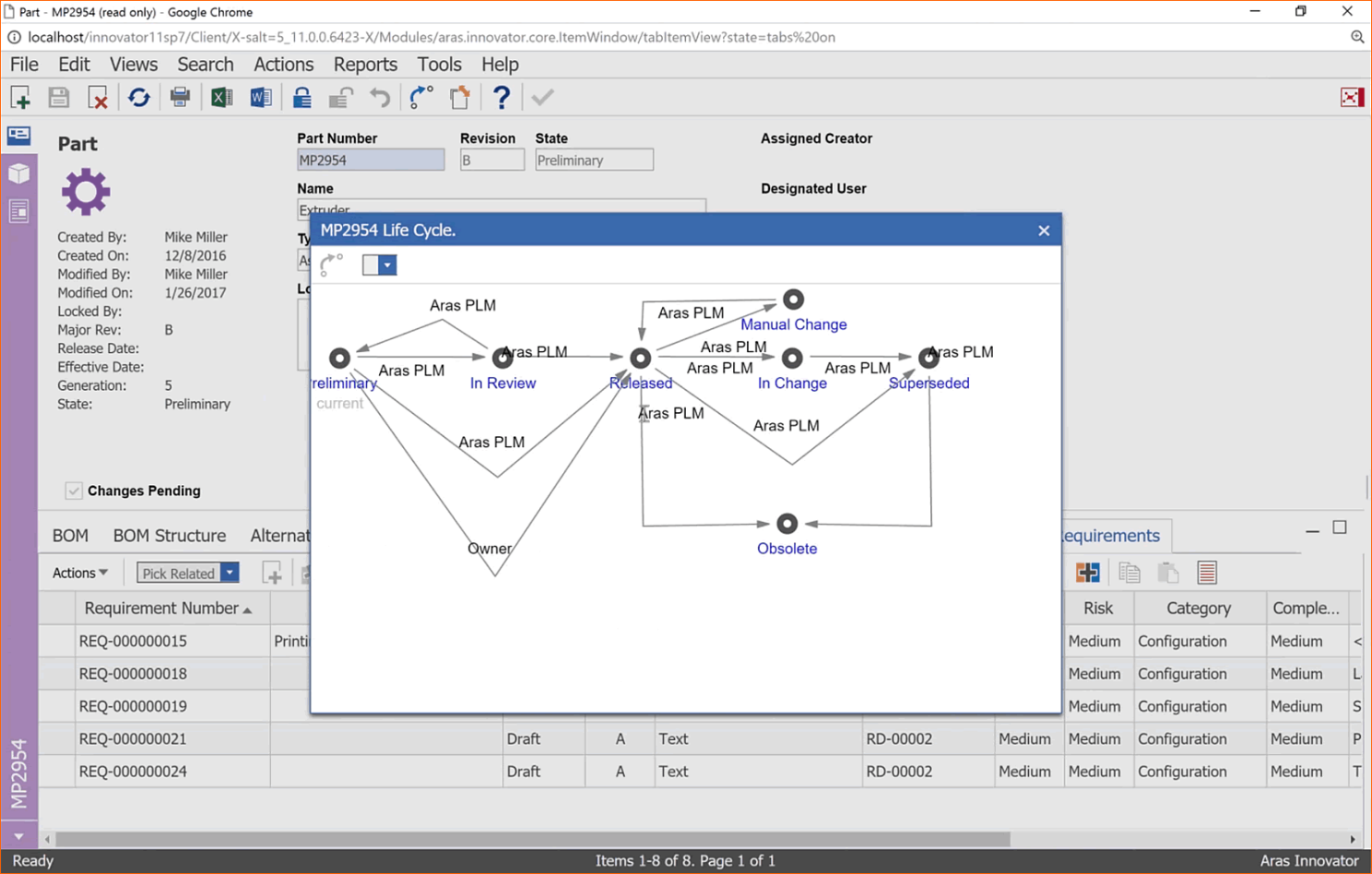

Under Siemens ownership, the former UGS products evolved into a comprehensive Digital Industries Software portfolio. NX (evolved from Unigraphics) became more than a CAD system—it integrated with Siemens’ manufacturing execution systems, industrial automation, and even their power grid technologies. Teamcenter (evolved from SDRC’s solutions) transformed from a PDM system into a comprehensive digital thread platform.

The German approach to PLM integration differed markedly from American or French strategies. Where American companies often prioritized rapid feature development and French companies emphasized elegant design experiences, Siemens focused on robust industrial integration. Their PLM solutions were designed to work seamlessly with factory automation systems, quality management processes, and the complex supplier networks that characterized German manufacturing.

Tecnomatix: Manufacturing Intelligence Becomes PLM

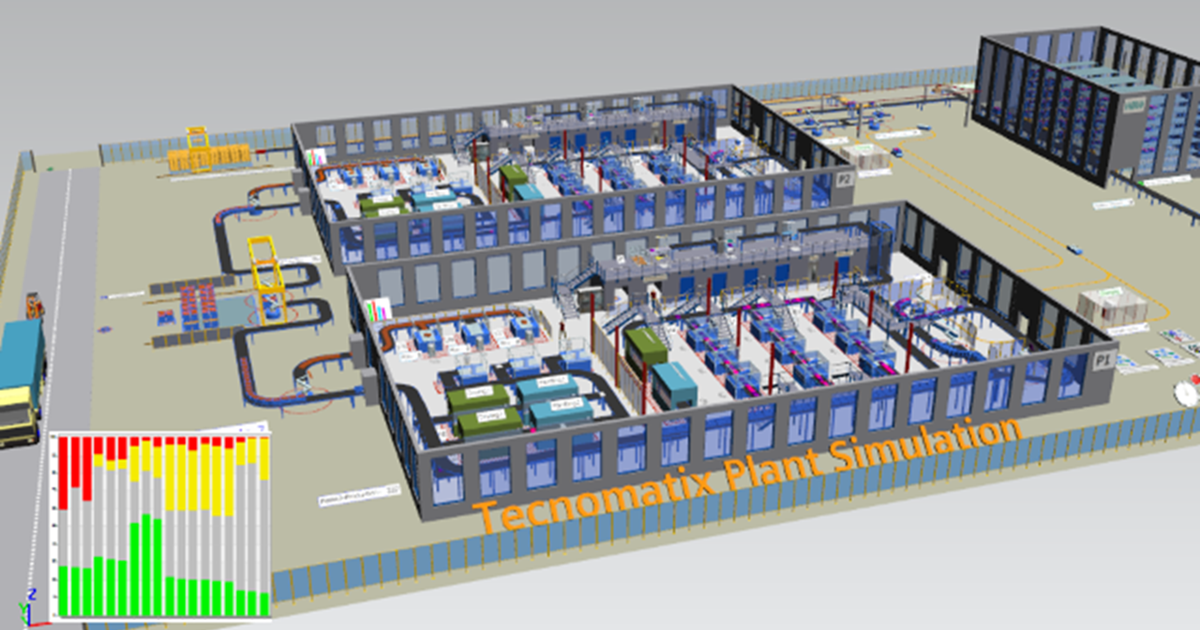

Siemens’ PLM strategy was further strengthened by the acquisition of Tecnomatix, an Israeli company with deep expertise in manufacturing simulation and optimization. Founded in 1983 by Moshe Mevorah, Tecnomatix had developed sophisticated capabilities for modeling and optimizing manufacturing processes—a critical gap in traditional PLM suites.

The integration of Tecnomatix into Siemens’ PLM portfolio represented a uniquely European approach to manufacturing intelligence. Rather than treating production as a downstream concern, Siemens embedded manufacturing considerations directly into the design process. This reflected the German industrial philosophy of “Industrie 4.0”—the belief that smart manufacturing required seamless integration between physical and digital systems.

Dr. Jan Mrosik, CEO of Siemens Digital Industries, explained the strategic vision:

“PLM isn’t just about managing product data—it’s about creating a complete digital representation of your industrial operations. When you can simulate not just the product, but the entire manufacturing process, you can optimize in ways that were never possible before.” (Source: Attributed to Dr. Jan Mrosik in Siemens corporate communications and industry interviews concerning the Digital Enterprise Suite.)

The German PLM Ecosystem: Specialized Solutions for Specialized Industries

Germany’s industrial diversity created opportunities for specialized PLM providers that served specific market niches. These companies reflected the German approach to technology—deep expertise in particular domains rather than broad horizontal platforms.

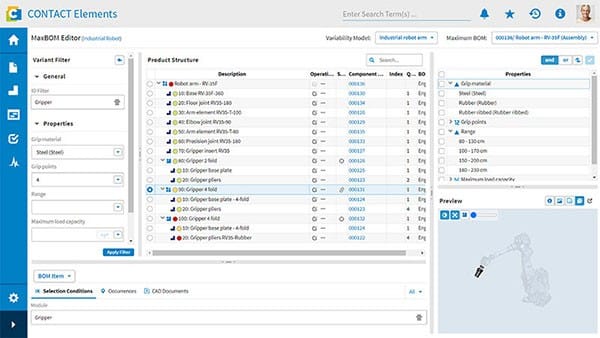

CONTACT Software, founded in 1990 in Bremen, exemplified this specialized approach. Rather than competing directly with the major PLM platforms, CONTACT focused on integration and workflow optimization—helping German manufacturers connect their diverse IT systems into coherent product development processes. Their Elements platform became popular among Mittelstand companies that needed PLM capabilities but couldn’t justify the complexity and cost of enterprise-level solutions.

The company’s success reflected a broader European trend toward PLM democratization—making advanced product development capabilities accessible to smaller manufacturers that formed the backbone of European industry. Klaus Kornwachs, CONTACT’s founder, described their philosophy:

“Not every company needs to be Boeing or BMW. But every manufacturer deserves access to the same digital capabilities that enable efficient product development. Our job is making sophisticated PLM accessible to the companies that actually make things.” (Source: Attributed to Klaus Kornwachs in various interviews and publications concerning CONTACT Software's mission.)

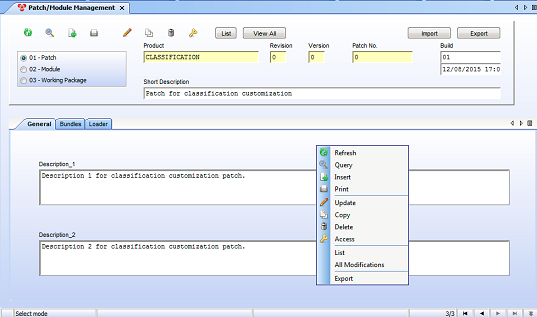

Eigner + Partner, founded in 1984 by Dr. Martin Eigner, took a different approach to specialization. Rather than focusing on specific industries, they concentrated on the academic and theoretical foundations of PLM. Their PDM system evolved into a comprehensive platform that emphasized the engineering management aspects of product development—reflecting the German tradition of rigorous, systematic approaches to industrial processes.

The company’s influence extended beyond their software products. Dr. Eigner’s academic work at the University of Kaiserslautern helped establish PLM as a legitimate engineering discipline, complete with theoretical frameworks and best practices. Notably, Dr. Eigner's influence extends to Aras Corporation, where he now serves on the Board of Advisors. Aras founder Peter Schroer was previously General Manager of Eigner + Partner's US operations, and Aras CTO Rob McAveney also held technical sales roles there. This connection underscores the lasting impact of Eigner's theoretical and practical contributions on the global PLM landscape, particularly on companies seeking flexible, adaptable PLM solutions.

Scandinavia: Sustainability Drives Innovation

The Nordic countries contributed a unique perspective to PLM evolution—one shaped by environmental consciousness, social responsibility, and the long-term thinking characteristic of Scandinavian industrial culture.

Sweden: Where Environmental Consciousness Meets Digital Innovation and Machining Dominance

Swedish companies pioneered the integration of environmental considerations into PLM processes decades before sustainability became a global priority. This wasn’t just corporate social responsibility—it reflected deep cultural values and regulatory requirements that made environmental impact a mandatory consideration in product development.

Technia, founded in 1984, emerged as one of Europe’s leading PLM consulting and implementation specialists. What distinguished Technia from American systems integrators was their focus on sustainable product development processes. Their implementations didn’t just optimize for speed and cost—they embedded environmental impact assessment, circular economy principles, and regulatory compliance into PLM workflows.

Anders Lundberg, Technia’s founder, explained their approach:

“In Sweden, you can’t separate good engineering from environmental responsibility. Our PLM implementations reflect this—every design decision includes consideration of environmental impact, recyclability, and social responsibility. This isn’t an add-on feature; it’s fundamental to how we think about product development.” (Source: Attributed to Anders Lundberg in interviews or company statements from Technia Transcat, focusing on their sustainability-driven approach.)

Technia’s influence extended across Europe as environmental regulations became more stringent and corporate sustainability commitments increased. Their methodologies for integrating lifecycle assessment, carbon footprint analysis, and circular design principles into PLM processes became templates for implementation across diverse industries.

Beyond traditional manufacturing, the fashion industry, epitomized by Swedish retail giant H&M, also played a role in pushing PLM development towards addressing rapid product cycles, supply chain transparency, and sustainability in consumer goods. While not a PLM software vendor, H&M's immense scale and global sourcing demands for fast-fashion cycles created unique needs for PLM solutions that could manage design, material sourcing, production tracking, and sustainability reporting across a vast and fast-moving product portfolio. This influenced the evolution of PLM systems with stronger capabilities for global collaboration, material lifecycle management, and sustainability tracking relevant to consumer industries.

Similarly, the packaging and food processing equipment giant Tetra Pak, headquartered in Sweden, represented another crucial driver for PLM in industrial equipment. Their complex machinery and long product lifecycles, coupled with stringent hygiene and safety regulations, demanded robust PLM systems for managing configurations, spare parts, service information, and regulatory compliance throughout the decades-long operational life of their equipment. This contributed to the development of PLM features critical for comprehensive after-sales service and maintenance.

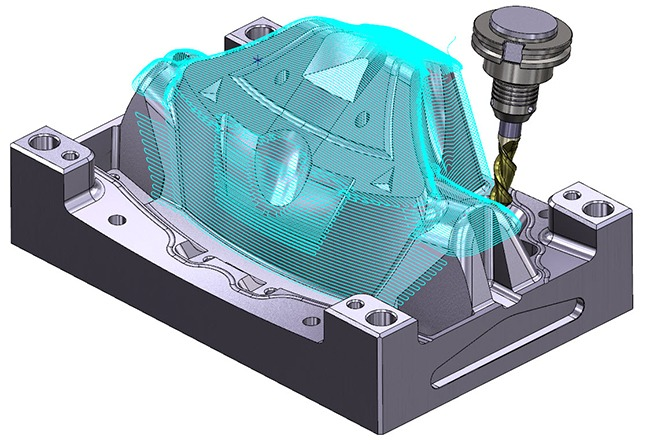

Sandvik: From Industrial Tools to Digital Manufacturing Leadership

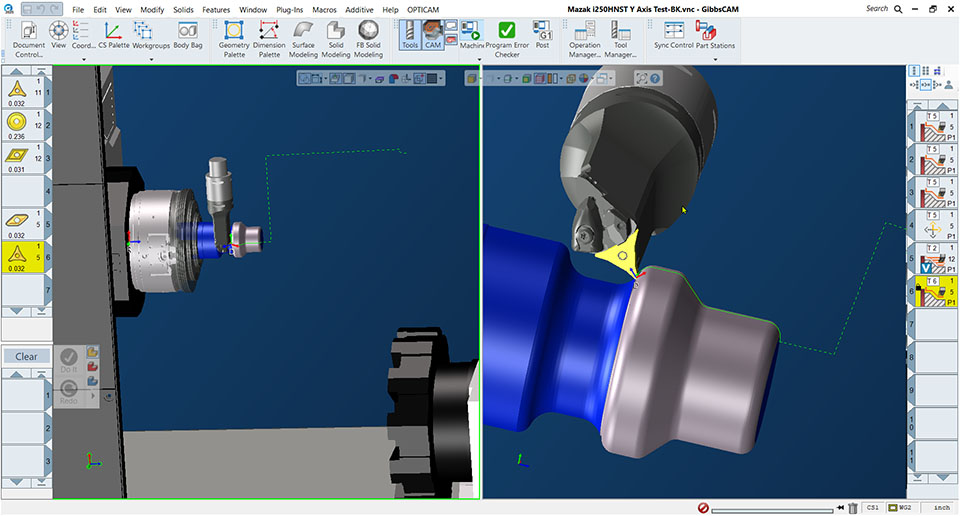

Sandvik, the Swedish engineering group best known for its advanced materials and cutting tools, has quietly become a global force in digital manufacturing and CAM (Computer-Aided Manufacturing). Through a series of strategic acquisitions—including CGTech (VERICUT) in 2020, Mastercam (via the acquisition of CNC Software) in late 2021, Cambrio (encompassing Cimatron, GibbsCAM, and SigmaNEST) in October 2021, and Dimensional Control Systems (DCS) in December 2021—Sandvik has consolidated a commanding position in the CAM software market, giving it direct influence over how machining processes are simulated, optimized, and executed worldwide.

This shift reflects a distinctly European industrial strategy: not chasing the broadest market, but building deep expertise in a critical domain that connects physical production with digital precision. By owning key CAM technologies, Sandvik ensures that the company can tightly integrate tool data, machining strategies, and real-world manufacturing processes into digital workflows.

The impact goes beyond CAM software itself. Sandvik’s integration of digital machining into its core business demonstrates how European industrial groups leverage software not as a side business, but as a natural extension of their manufacturing DNA. In doing so, Sandvik embodies the Scandinavian balance of industrial heritage, precision engineering, and sustainability—pushing PLM and CAM toward smarter, more resource-efficient production.

Hexagon: Sweden’s Quiet Giant in Industrial Software

While Technia pioneered PLM consulting and H&M brought fast fashion into digital supply chains, Sweden also became home to one of the most consequential consolidators in engineering software: Hexagon AB.

Founded in 1975 and long associated with precision measurement systems, Hexagon began a dramatic pivot in the 2000s—moving from metrology hardware into digital solutions spanning design, simulation, and manufacturing. Through an ambitious acquisition strategy, it built a software portfolio that rivaled Dassault Systèmes and Siemens in breadth.

In simulation, Hexagon stunned the market by acquiring MSC Software in 2017, one of the oldest CAE firms with roots in NASA’s space program. But in September 2025, Hexagon announced the sale of MSC to Cadence Design Systems, exiting mainstream simulation and refocusing its strategy.

The result is a leaner Hexagon—one that doubles down on its historic strengths in metrology, manufacturing intelligence, and CAM. This pivot highlights Hexagon’s long-term strategy: link measurement, machining, and shop-floor intelligence into a closed-loop system that connects the digital and physical worlds.

Conclusion for Sweden

Sweden today holds a unique position in global manufacturing software. With Sandvik acquiring Mastercam and GibbsCAM, and Hexagon owning Edge CAM, ESPRIT CAM, Radan, NC Simul, a majority of the most widely adopted CAM packages in machine shops worldwide now both fly the Swedish flag. For decades, machinists from Ohio to Osaka debated whether Mastercam or GibbsCAM was the better fit for their spindles; few realize that both now report back to Stockholm. Add Hexagon’s metrology empire and Sandvik’s tooling heritage, and Sweden quietly commands the digital heart of subtractive manufacturing. In a landscape usually dominated by American and German giants, it is a remarkable reminder that Europe’s north has become the capital of CAM.

Norway: Maritime Heritage Drives Specialized Solutions

Norway’s maritime and offshore energy industries created unique demands for PLM solutions that could handle extreme environmental conditions, complex regulatory requirements, and the long service lives characteristic of marine and offshore installations.

Norwegian companies developed specialized PLM capabilities for industries where product lifecycles span decades and failure isn’t an option. These solutions emphasized robust configuration management, comprehensive change tracking, and the ability to maintain detailed service histories over extended periods.

The Norwegian approach to PLM reflected the country’s maritime heritage—products had to work reliably in harsh conditions, with minimal opportunity for repair or replacement. This drove innovations in predictive maintenance, digital twin technology, and remote monitoring capabilities that would later influence PLM development globally.

The UK: From Aerospace to Automotive Excellence

Britain’s contribution to European PLM development was shaped by its aerospace and automotive industries, both of which demanded sophisticated product development capabilities while facing intense international competition.

BAE Systems and the Military-Industrial PLM Complex

The UK’s defense industry, centered around companies like BAE Systems, created unique requirements for PLM systems that could handle complex security requirements, international collaboration constraints, and the exacting standards of military procurement.

These requirements drove innovations in access control, audit trails, and configuration management that became standard features in enterprise PLM systems. The need to collaborate with international partners while maintaining security led to sophisticated approaches to data sharing and workflow management that influenced PLM architecture across industries.

Mathematical Foundations and Complex Product Lifecycles

While British industry drove practical applications, academic institutions also played a foundational role. The University of Cambridge, particularly its Computer-Aided Design Centre (CADCentre) established in the 1960s, was instrumental in developing the mathematical foundations for 3D CAD modeling, including geometric kernels, which underpin many modern PLM systems. This intellectual contribution, crucial to the "Kernel Wars" that shaped the CAD industry, highlights the deep scientific roots of British engineering innovation.

The challenges faced by companies like Rolls-Royce illustrate the demanding nature of UK manufacturing. For Rolls-Royce, managing the product lifecycle of highly complex products like aircraft engines, some of which remain in service for over 50 years, presents immense PLM hurdles. This includes supporting engines designed in the 1950s, bridging data silos from legacy systems (e.g., spreadsheets and disconnected tools), seamlessly integrating stringent regulatory requirements into designs, and enabling secure and efficient collaboration across a global enterprise. Their drive for digital transformation and digital threads is aimed at connecting engineers to critical data and streamlining complex processes.

On the other end of the product lifecycle spectrum, Red Bull Racing in Formula 1 exemplifies the extreme demands for rapid PLM iteration. With car designs evolving on a weekly basis, their PLM challenges revolve around improving consistency in carbon fiber parts, drastically reducing lead times for manufacturing and assembly, and optimizing the design and manufacturing process for constant change. Their reliance on advanced PLM tools (like Siemens NX and Teamcenter) and specialized simulation software (like Fibersim) highlights the need for systems that can accelerate design, manufacturing, and testing within incredibly tight deadlines, demonstrating PLM's critical role in high-performance, fast-paced environments.

The Swiss Precision Factor

Switzerland’s contribution to PLM development reflected the country’s reputation for precision, quality, and discrete excellence. Swiss companies rarely sought to dominate markets through aggressive scaling—instead, they focused on creating precisely engineered solutions for specific high-value applications.

The Swiss focus on standards and interoperability reflected broader European values around collaboration and long-term thinking. Rather than seeking to lock customers into proprietary ecosystems, Swiss PLM providers emphasized openness and integration—recognizing that European industry’s complexity required flexible, standards-based approaches.

A notable aspect of the Swiss PLM landscape, particularly in the luxury goods sector, is the critical adoption of systems like PTC's Windchill. Companies like Rolex and Bulgari, renowned for their exquisite craftsmanship, precise engineering, and long product lifecycles, rely heavily on robust PLM systems to manage complex product data, design iterations, materials sourcing, and intricate manufacturing processes. Windchill's capabilities in product data management, change management, and quality control have been crucial for these high-value manufacturers to maintain their impeccable standards and ensure traceability across their highly specialized production. The demanding requirements of precision and heritage in luxury goods pushed PLM systems to offer unparalleled data integrity and detailed configuration control.

The European PLM Service Provider Ecosystem

The complexity of European PLM implementations—with their emphasis on regulatory compliance, environmental considerations, and integration with existing industrial systems—created opportunities for specialized service providers that understood both the technology and the business context. Given Europe's diverse national cultures, varied business practices, and multiple languages, the role of local systems integrators and consulting firms is particularly vital. They bridge the gap between global PLM software solutions and specific regional, industry, or company needs, ensuring successful adoption and optimization.

XPLM, founded in 1999, is a prominent example of a European PLM consulting firm. XPLM distinguished itself by focusing on the integration of various PLM solutions and providing expert consulting to European manufacturers. Their approach reflected distinctly European values: long-term relationships over transactional engagements, deep industry expertise over broad technical skills, and integration with existing business processes over revolutionary transformation.

Beyond XPLM and Technia, numerous other regional and national service providers have been crucial. Companies like CIMPA (a subsidiary of Airbus, specializing in PLM consulting), PLM Group (serving Nordic and Baltic markets), and many smaller, specialized consultancies across Germany, Italy, and other countries have played a critical role. These firms often possess specific industry vertical expertise (e.g., automotive, aerospace, machinery), deep knowledge of local regulatory environments, and the ability to navigate cultural nuances. Their importance lies in their capacity to provide tailored integration services, customize solutions, offer localized training, and ensure smooth PLM deployments that align with the specific operational realities and cultural context of individual European manufacturers.

Integration and the European Digital Thread

By the 2010s, European PLM development had evolved beyond individual tools or platforms to encompass comprehensive digital ecosystems. The European approach to digital transformation differed significantly from American models—rather than “moving fast and breaking things,” European companies prioritized careful integration, robust testing, and seamless operation with existing systems.

This philosophy culminated in the concept of the “digital thread”—a comprehensive digital representation of products from initial concept through end-of-life recycling. European implementations of digital thread concepts emphasized environmental tracking, regulatory compliance, and social responsibility in ways that reflected broader European values.

The integration of Industry 4.0 concepts with PLM systems created uniquely European solutions that balanced technological sophistication with practical manufacturability. These systems didn’t just optimize for efficiency—they embedded considerations of worker safety, environmental impact, and social responsibility that reflected European industrial culture.

Legacy and Future: European PLM in the Age of Sustainability

As PLM systems evolved into the 2020s, European leadership became increasingly apparent in areas that reflected broader European priorities: sustainability, regulatory compliance, and long-term thinking. While American PLM systems often prioritized rapid feature development and Asian systems focused on cost optimization, European solutions embedded environmental and social considerations as fundamental design principles.

The European Union’s increasing emphasis on circular economy principles, carbon neutrality, and supply chain transparency created new requirements for PLM systems that European providers were uniquely positioned to address. Their decades of experience with complex regulatory environments and stakeholder management translated into competitive advantages as global companies faced increasing pressure to demonstrate environmental and social responsibility.

Dassault Systèmes’ Virtual Twin concept represented the culmination of European PLM thinking—comprehensive digital representations that could model not just product performance, but environmental impact, social consequences, and long-term sustainability implications. This holistic approach reflected European values that prioritized societal benefit alongside commercial success.

Siemens’ Digital Enterprise Suite integrated PLM with industrial automation, energy management, and sustainability reporting in ways that reflected German industrial expertise and European regulatory requirements. Their solutions didn’t just optimize individual products—they enabled comprehensive optimization of industrial ecosystems.

Conclusion: The European PLM Philosophy

European PLM development has been characterized by several distinctive themes that reflect broader European industrial culture:

Long-term thinking over short-term optimization—European PLM systems are designed to support products and processes over decades, not quarters.

Integration with existing systems rather than revolutionary replacement—reflecting the reality of European manufacturing, where new technologies must work seamlessly with established industrial processes.

Regulatory compliance and social responsibility as fundamental design principles, not afterthoughts—European PLM systems embed environmental and social considerations because European industry has always been required to consider these factors.

Collaborative ecosystems rather than proprietary platforms—European PLM providers have generally emphasized interoperability and standards, recognizing that European industrial complexity requires flexible, open approaches.

Precision and reliability over rapid iteration—reflecting European industrial culture that prioritizes getting things right the first time rather than rapid prototyping and iteration.

As the global economy faces increasing pressure to address climate change, supply chain transparency, and social responsibility, the European approach to PLM—with its emphasis on comprehensive lifecycle thinking, regulatory compliance, and stakeholder integration—appears increasingly prescient.

The collegiate glass and steel campus of Vélizy-Villacoublay and the industrial landscapes of the German Mittelstand may seem worlds apart from Silicon Valley’s startup culture, but they represent a different path to technological innovation—one that balances commercial success with environmental responsibility and social benefit. In an age where technology must serve not just efficiency but sustainability, the European PLM legacy offers valuable lessons for the future of product development worldwide.

This article synthesizes the European PLM evolution, highlighting contributions often overshadowed by American technological narratives but increasingly relevant as global priorities shift toward sustainable and responsible product development.